Consumer Goods and Additive Manufacturing

Defining a consumer good today is not straightforward; the spectrum ranges from essential necessities like the food we purchase to durable products like cars or electronic devices. One thing is certain: these products are sold to the end consumer seeking items that meet their desires. If there’s a manufacturing technique that offers customization options for consumer goods, it is additive manufacturing. In some instances, it even allows consumers to participate in creating the final object—for example, in the footwear industry, a sneaker is created after its wearer has had their feet scanned.

Thanks to additive manufacturing, the consumer goods sector can offer made-to-order products that are also more efficient, comfortable, aesthetically pleasing, and practical. This is where the added value of 3D printing lies: it enhances product functionality while catering to the end consumer’s needs.

Why is this technology considered useful for consumer goods?

Additive manufacturing, or 3D printing, is particularly beneficial for consumer goods for several compelling reasons:

Customization: One of the most significant advantages is the ability to personalize products to meet individual consumer needs and preferences. This level of customization can range from simple color choices to complex design modifications tailored to specific user requirements.

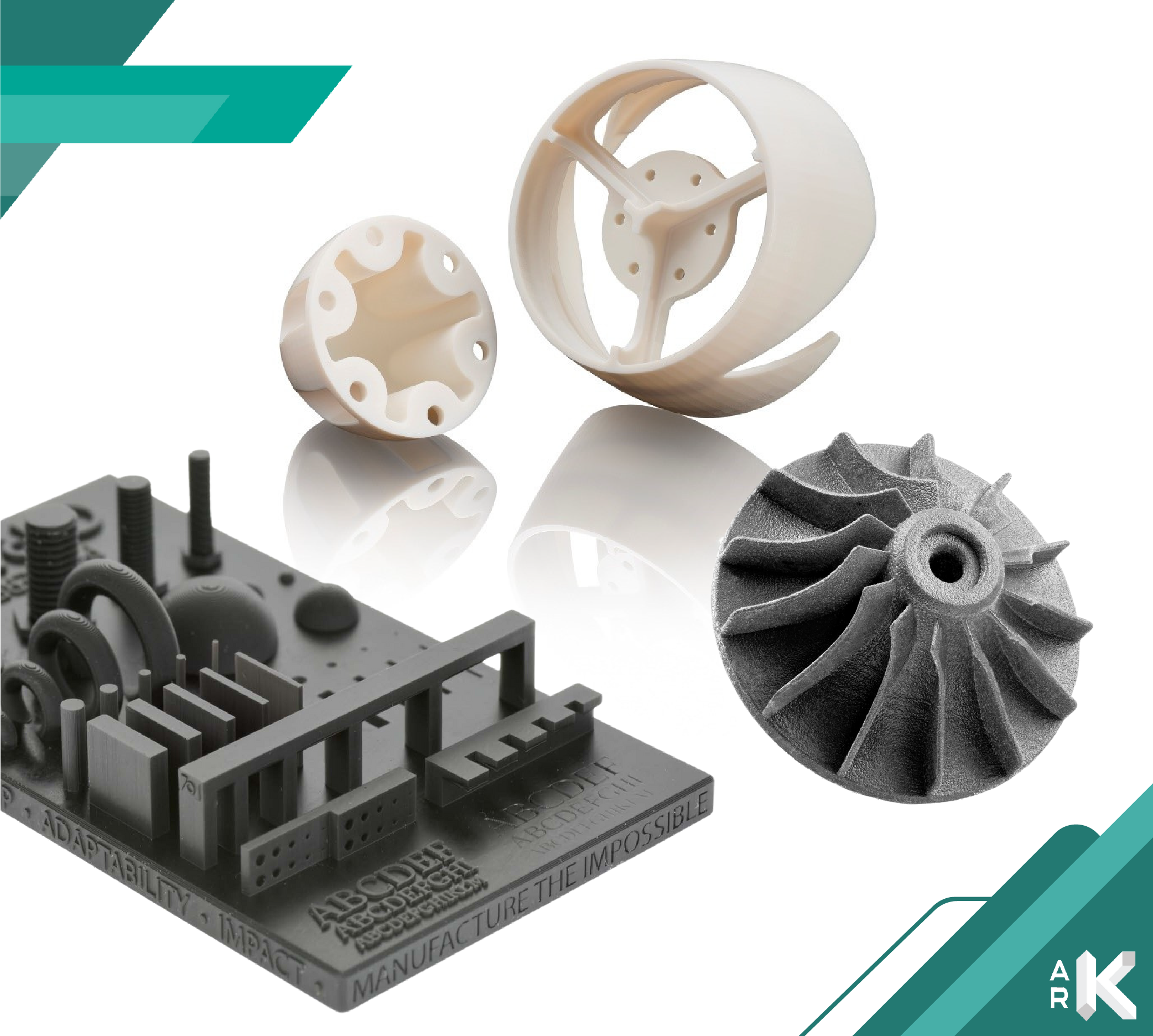

Flexibility in Design: Additive manufacturing allows for the creation of complex and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for product innovation and differentiation in the consumer goods market.

Reduced Time to Market: 3D printing can significantly speed up the development process from design to final product, allowing companies to respond more quickly to market trends and consumer demands.

Cost-Effective Prototyping: It enables cost-effective prototyping by eliminating the need for expensive molds and tooling for each new design, reducing the initial investment required to bring a product to market.

Sustainability: Additive manufacturing can be more sustainable than traditional manufacturing processes. It reduces waste by using only the material needed to create the product, and it can utilize eco-friendly materials, contributing to the production of greener consumer goods.

On-Demand Production: Companies can produce goods on demand rather than in large batches, reducing inventory costs and waste. This also allows for the production of niche products that might not be viable using mass production techniques.

Enhanced Product Functionality: With the ability to test and refine prototypes easily, designers can optimize product designs for better performance, durability, and user experience.

Supply Chain Optimization: By enabling local production close to the end user, 3D printing can reduce the need for long supply chains, lowering transportation costs and the carbon footprint associated with shipping products globally.

In summary, additive manufacturing offers unparalleled flexibility, efficiency, and customization capabilities for consumer goods, making it a transformative technology for the industry.

The advantages of 3D printing models; the advantages of additive manufacturing technology for consumer goods

Rapid Prototyping

Customization and Personalization

Complexity without Additional Cost

Reduced Waste

Supply Chain Simplification

Accessibility to Innovation

Material Diversity

Economic Production of Low Volumes

Enhanced Product Performance

Integration of Multiple Parts into Single Assemblies

These advantages highlight the transformative potential of additive manufacturing in the consumer goods sector, offering innovative ways to design, produce, and deliver products that meet the evolving demands of modern consumers.

The most exciting applications in manufacturing within the consumer goods industries

The field of consumer goods is witnessing a revolution thanks to additive manufacturing (AM), with some of the most exciting applications showcasing the versatility and innovation that 3D printing brings to the industry. Here are several compelling examples:

Companies like Adidas and Nike are using 3D printing to create customized shoes tailored to an individual's foot shape and walking style. This not only enhances comfort but also performance, offering a personalized product that was difficult to achieve at scale before.

3D printing is being used to produce wearable technology, such as smartwatches and fitness trackers, with custom-fit designs. This includes everything from the device casings to flexible bands, allowing for a high degree of personalization and functionality.

The eyewear industry is utilizing 3D printing to offer glasses and sunglasses that are custom-fitted to the wearer's facial features. This improves comfort and style, allowing consumers to design their eyewear to match their personal aesthetics.

Additive manufacturing enables the creation of intricate and personalized jewelry designs that would be challenging or impossible to produce with traditional methods. Consumers can have a hand in designing their unique pieces, which are then precisely crafted through 3D printing.

Designers are exploring 3D printing for on-demand fashion, creating everything from haute couture dresses to unique accessories. This approach reduces waste by producing items only when they are needed and allows for rapid prototyping of new designs.

From dental aligners tailored to the patient's oral geometry to personalized prosthetics that fit perfectly to the wearer's body, 3D printing is making significant strides in health and wellness, offering products that are both functional and tailored to the individual.

Additive manufacturing enables designers to create unique home decor items and furniture with complex designs that reflect individual style preferences. This includes lighting fixtures, vases, and even chairs that combine functionality with artistic expression.

Customizable and interactive toys and educational tools are being developed using 3D printing, providing engaging learning experiences for children. This includes everything from personalized action figures to educational models that demonstrate complex scientific concepts.

Companies are using 3D printing to produce goods from recycled or bio-based materials, contributing to a more sustainable approach to consumer products. This includes items like sunglasses made from recycled plastics and biodegradable household products.

Though still in its infancy, 3D printing of food offers exciting possibilities for customization in terms of shape, texture, and nutrition, potentially revolutionizing the culinary industry by allowing for highly personalized dietary needs and preferences.